Ensiling rice straw in China and India : when bio-fermentation turns crop residues into valuable animal feed resources

Yanfen Cheng1, M. R. Garg2, Guanghui Hu1, Varijakshapanicker Padmakumar3, Harinder P.S. Makkar4

1Nanjing Agricultural University, Nanjing, China

2Independent Consultant, Ambala, India (Formerly at NDDB, Anand, India)

3International Livestock Research Institute, Kathmandu, Nepal

4International Consultant, Sustainable Bioeconomy, Vienna, Austria (Formerly at FAO/IAEA, University of Hohenheim)

Introduction

Both China and India produce a substantial amounts of crop residues and both countries are short of feed resources. Crop residues could be valuable feed resources; however, these are burnt in both countries, causing environmental pollution. In addition, it is a waste of nutrients that could be used to raise ruminant livestock. Efforts are being made to introduce innovative technologies so as to enhance their use as animal feed. Against these settings, here we present two case studies, from China and India for biofermentation of rice straw which has increased its utilization as animal feed. The approaches could also be used for other straws such as wheat, sorghum, barley, among others.

Case study from China

Utilization of crop residues as feed resources is highly important for China

In recent years, with the rapid development of livestock, China's demand for feed resources has been on the rise. Meeting the insufficient domestic feed supply has become a significant challenging for the sustainable development of the livestock industry.

As shown in Figure 1, China imports approx. 160 million tons of crop grains annually, including soybean, barley, wheat, corn, rice, sorghum, among others. For example, China imported 157.53 million metric tons of crop grains in 2024, which included 105 million metric tons of soybean, accounting for over 60% of global soybean trade. Furthermore, China imported 11.24 million metric tons of barley, 11.01 million metric tons of wheat, 13.76 million metric tons of corn, and 8.66 million metric tons of sorghum in 2024. A big proportion of these imported crop grains was used as a feed resource. Besides, China imported more than 2 million metric tons of high-quality forages, such as alfalfa pellets, which accounted approx. 40% of its demand. The international prices of these crops, especially soybean and corn, are highly volatile due to geopolitical conflicts and extreme weather, leading to the high cost of feed resources and low economic benefit for farmers.

Figure 1. The annual imported crop grains in China from 2021 to 2024

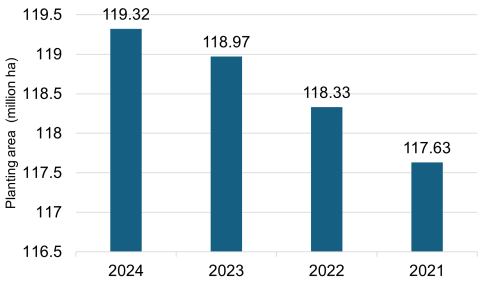

At the same time, to support the food intake of 1.4 billion people, China cultivates many crops. Figure 2 shows the planting area of crops, of which corn, rice, and wheat are the top three crops. After harvesting, a substantial amount of crop residues is left, which can be potentially used as feed resources.

Figure 2.a. Planting area of crops in China: total planting area of all crops

Figure 2.b. Planting area of rice, wheat, and corn, in China

In 2022, the potential crop residue availability reached 840 million metric tons, including 208 million metric tons of rice straw, 161 million metric tons of wheat straw, and 288 million metric tons of corn stover. These three major types of straw accounted for more than 78% of the total production. Once the crop residues can be used as a feed resource efficiently, China’s import of crops might decrease dramatically. In addition, the cost of feed resources would also decrease. So, innovative technologies for efficient crop residue utilization as feed resource is beneficial for both the government and the farmers. Environment is also protected because a large amount of straws is burnt. Here, we use rice straw as an example to describe what can be done to improve the utilization of crop residues as feed resources.

Low feed efficiency is the problem in the crop residues as feed resources, and potential strategies to improve their feed efficiency

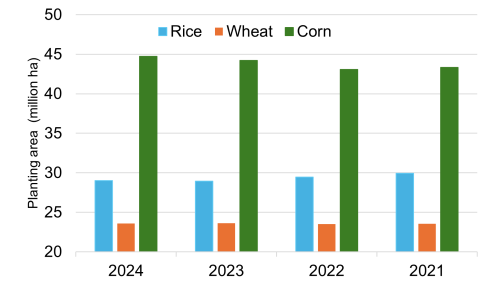

In 2024, we collected literature on the chemical composition of rice straw produced in China and conducted a meta-analysis. As shown in Table 1, the chemical components of rice straw varied significantly. The content of neutral detergent fibre (NDF) is relatively high with the mean value of 68%, of which the content of cellulose (37%) is higher than that of hemicellulose (25%). The content of lignin, which links to hemicellulose, is 13%. It means that the ratio of hemicellulose to lignin is approx. 2 (Hu et al., 2025).

Table 1. Chemical composition of rice straw in China (%DM) (Hu et al., 2025)

DM = dry matter, Mean = mean value, Min = minimum value, Max = maximum value, SE = standard error, CV = coefficient of variation,

CP = crude protein, EE = ether extract, CEL = cellulose, HEM = hemicellulose, LIG = lignin, NDF = neutral detergent fibre, NFC = non-fibre carbohydrates.

Thereafter, we conducted correlation analysis on the chemical components of the straw and it’s in vitro dry matter digestibility. Results showed that the in vitro dry matter digestibility was positively correlated to the contents of crude protein (R2=0.43, P<0.01) and ether extract (R2=0.57, P<0.01), and negatively correlated to the content of NDF (R2=-0.37, P<0.01), especially to the content of cellulose (R2=-0.65, P<0.01) (Hu et al., 2025). It implies that the increasing content of NDF would lead to the decrease in digestibility of rice straw.

Besides the chemical components, the increasing CO2 concentration and temperature would also lead to a decrease in the dry matter digestibility. Hu et al. (2015) evaluated the effects of increased atmospheric temperature and CO2 concentration during crop growth on the chemical composition and in vitro rumen fermentation characteristics of wheat straw. Results showed both CO2and temperature could affect the chemical components of the straw. The combination of CO2 and temperature treatments had a higher effect than that of the individual treatment. Compared to the control, the contents of dry matter, ether extract, and NDF were significantly increased in the group that implied both CO2 and temperature treatment, while the content of crude protein was significantly decreased. In vitro dry matter digestibility analysis showed that gas production, ammonia nitrogen, microbial crude protein, and volatile fatty acids were significantly decreased in the combined treatments of CO2 and temperature. The results imply that the digestibility and feed efficiency of crop residues would decrease with the ongoing global warming.

It is important to understand the basic knowledge on the structure of plant fibre for developing innovative strategies that enhance dry matter digestibility and feed efficiency of crop residues and use them as livestock feed. Plant fibre, includes cellulose, hemicellulose, and lignin. Hemicellulose and lignin link together to form a net surrounding cellulose. It means that we need to break down the linkages between hemicellulose and lignin to release cellulose for the upcoming degradation by microorganisms.

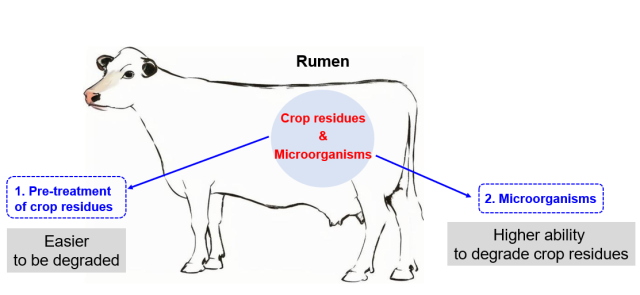

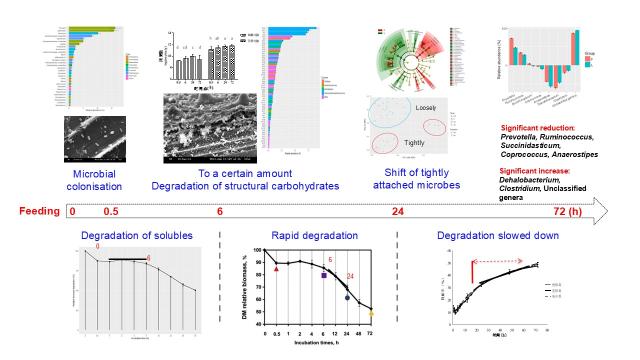

Equally important is to understand basic steps in the digestion of crop residues in the rumen. For this, we conducted research to demonstrate how the crop residues are degraded in the rumen. Figure 4 shows the temporal degradation of rice straw in the rumen of dairy cow. Briefly, the degradation of crop residues can be divided into 3 stages. The first stage (within 6 hours after feeding) is the “microbial colonization”. At this stage, microbes colonise the plant fibre and use the soluble components to grow. The aim is to obtain enough microbes for upcoming degradation. Once the number of microbes reaches a threshold, the degradation goes into the second stage, “rapid degradation”. At this stage, the microbes and their enzymes degrade the plant in a rapid manner. The digestibility of dry matter, crude protein, and NDF are high and a large amount of short chain fatty acids (volatile fatty acids) are produced. After 24 hours of feeding, the degradation goes to the third stage, “slow degradation”. At this stage, the speed of degradation is slowed down, and there is a change in the type of microbes that colonise the plant fibre. It means another group of microbes in the rumen is responsible for degradation of the remaining highly complex plant fibre. Notably, the relative abundance of unclassified genera significantly increases, implying that our knowledge to understand this stage is very limited (Cheng et al., 2017).

Figure 3. Proposed strategies to improve the feed efficiency of crop residues

Figure 4. Microbial colonisation and degradation of rice straw in the rumen (Cheng et al., 2017)

Based on the above knowledge, we proposed two potential strategies to improve the efficiency of crop residue utilization (Figure 4). The first strategy is to pretreat the crop residues, which loosens the physical and chemical structure of crop residues and subsequently improves its degradation in the rumen, especially the degradation at the second stage, “rapid degradation”. Physical, chemical, and biological pretreatments are the predominant methods. Physical pretreatment includes mechanical comminution, steam explosion, thermal treatment, irradiation, ultrasonication, extrusion, high-pressure homogenization, cryogenic milling, etc. These treatments are energy-hungry and increase the costs of the treated feed resources. Chemical pretreatment includes alkali treatment, acid treatment, oxidative treatment, sulfonation, the combination of several chemicals, etc. As wastewater needs additional processes to remove the chemicals, chemical pretreatment causes environmental issues. Biological pretreatment includes microbial treatment, enzymatic treatment, anaerobic digestion, combined bio-pretreatments, etc. These pretreatments require low-energy input and are environmentally friendly. Such treatments are recommended to pretreat crop residues in China and are becoming popular. Details of these treatments are given in the later sections.

The second potential strategy is to improve the ability of ruminal microorganisms, especially those microorganisms such as Prevotella involved in the degradation of crop residues at Stage 2, “rapid degradation”. This requires improvement in the number of key microorganisms as well as of the excreted plant-fibre degrading enzymes in the rumen. This strategy is beyond the scope of this paper and hence not dealt with.

Silage (bio-fermentation) is a practical and economic way to improve the feed efficiency of crop residues

Here we present bio-fermentation of rice straw as an example. The focus is on the treatment of the straw and its feeding to the growing animals.

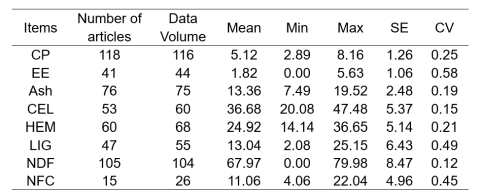

In Jiangsu, China, the amount of green rice straw production is approx. 15.0 metric tons/ha. The green rice straw is used for the bio-fermentation within 48 hours after the harvest, usually within 24 hours. The specific steps for preparation of the bio-fermented rice straw are as follows (Figure 5):

- Harvesting. Using machines to harvest the rice straw along with collection of grains.

- Chopping. After transporting the rice straw to the factory, the rice straw is chopped to 2-5 cm with a straw chopper. It may be noted that the length of rice straw is very important. If the length is too short, it would reduce rumen motility and increase the passage rate of forage, reducing nutrient absorption. If the length is too long, it would affect the quality of bio-fermentation (air cannot be removed thoroughly which is required to create anaerobic conditions).

- Adjusting the moisture. The ideal moisture for the bio-fermentation is 60-70%. When we squeeze the rice straw, a ball should be formed. If the rice straw is too dry, water can be sprayed. If the rice straw is too wet, mixing it with some dried hay or bran will absorb the moisture. At this step, we can consider adding some lactic acid bacteria to improve the quality of bio-fermented rice straw. As shown in Table 1, the content of non-fibre carbohydrates in rice straw might be insufficient to support microbial growth. Some substrates to promote the growth of the lactic acid bacteria may be added. Molasses and urea are low-cost good substrates for growth of lactic acid bacteria. Note: The lactic acid bacteria and their substrates are optional. Nowadays, in China, farmers usually add them while preparing silages as these can stimulate the growth of lactic acid bacteria, leading to the production of enough lactate in a short time. For the amount of, and how to add, the lactic acid bacteria and substrates, instruction from the commercial firms can be followed. During the last few years, we collaborated with Nanjing Nature Bio-Tech Co., Ltd to develop a commercial lactic acid bacteria product. According to their instructions, addition is at a level of 1 gram/metric ton fresh rice straw (or grasses) and 2 gram/metric ton dried rice straw (forage hays).

- Filling and compaction. The chopped rice straw is then filled in silos, 30-50 cm per layer and compacted with tractors or manually. The required density is above 650 kg/m3. It is recommended to use tractors to compact the rice straw to remove as much air as possible and shorten the time for the preparation. The rice straw can also be baled in plastic sheets using a tractor driven baler. Note: There are three types of infrastructure used for the biofermentation of straw: silo pit, silo tower, and bales. For farmers who prepare and use it themselves, silo pit or silo tower is a good option. Bales are easier to transport, and are used for selling to the livestock farmers

- Sealing and anaerobic management. After finishing the filling and compaction, a plastic film is used to cover the straw filling. Usually, tires or sandbags are used on top of the film to keep the rice straw under anaerobic conditions. It is to be ensured that the material is in anaerobic condition during fermentation. Therefore, inspection of the pits almost every day to check the film laid on the top for damage by rodents or birds is necessary. Also it is important that the edges are sealed tightly.

- Fermentation. The fermentation can be divided into three stages. The initial stage is the first 3 days, when aerobic microbes are active and use-up oxygen present. The temperature rises to 40-45°C. After the consumption of oxygen, in the second stage, lactic acid bacteria grow and pH drops dramatically, with accumulation of lactate. Usually, the pH can drop to less than 4.2. Sometime, without addition of lactic acid bacteria and substrates, the pH would drop to approx. 4.5 for rice straw. After that, is the stabilization stage. At this stage, the straw is under anaerobic condition at constant low pH. The fermented straw can be preserved for more than 1 year without damage. Note: For the bio-fermentation of rice straw, the minimum fermentation time is 21 days under Chinese conditions; however, we usually keep it for 45-60 days. If the content of plant fibre is high, we recommend keeping it longer, the lactate and low pH can also act as chemical treatment of rice straw.

There are several standards to evaluate the quality of the bio-fermented rice straw, including odor, color, pH, mold rate, the concentrations of lactate, acetate and butyrate, etc. A high-quality bio-fermented rice straw is pleasant sour (lactic acid), yellow-green (original) in colour, contains less than 5% of mold, and the pH ranges 3.8-4.2.

Figure 5. The process of preparing rice straw silage (Sources: https://bit.ly/3IKpu3n; https://bit.ly/44JSalP)

When the pit is open, oxygen goes into the pit. The aerobic microbes which were inhibited in the anaerobic condition start growing rapidly and leads to “secondary fermentation”. Secondary fermentation is not good for the straw and must be prevented by minimizing exposure of the bio-fermented rice straw to the air.

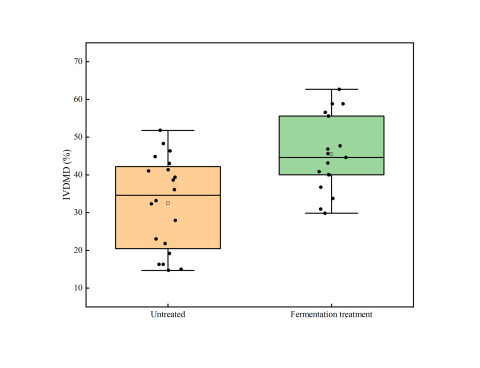

We conducted a meta-analysis to compare the in vitro digestibility of rice straw before and after bio-fermentation. Data showed that the bio-fermentation increased the in vitro digestibility of rice straw by approx. 8% (Figure 6). It implies that bio-fermentation might be a good option to improve the efficiency of rice straw utilization as animal feed.

IVDMD = in vitro dry matter digestibility

IVDMD = in vitro dry matter digestibility

Figure 6. Comparison of in vitro digestibility of rice straw before and after bio-fermentation (Hu et al., 2025).

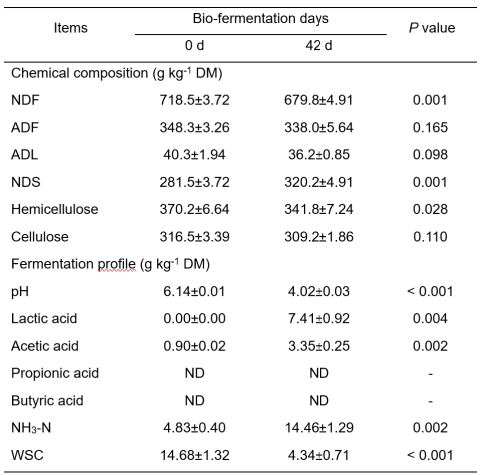

On using the commercial lactic acid bacteria developed with Nanjing Nature Bio-Tech Co., Ltd to pretreat the rice straw, good results were obtained. As shown in Table 2, the contents of NDF and hemicellulose were significantly decreased and the content of neutral detergent soluble (NDS) was significantly increased which means the hemicellulose was converted to the solubles during the bio-fermentation (Xu et al., 2023). The pH value after bio-fermentation was 4.0. A combination of lactic acid and acetic acid was present, suggesting formation of a good bio-fermented rice straw.

Table 2: Chemical components and fermentation profiles of rice straw before and after bio-fermentation for 42 days (Xu et al., 2023), n=5

NDF = neutral detergent fibre, ADF = acid detergent fibre, ADL = acid detergent lignin,,

NDS = neutral detergent soluble, WSC = water soluble carbohydrate.

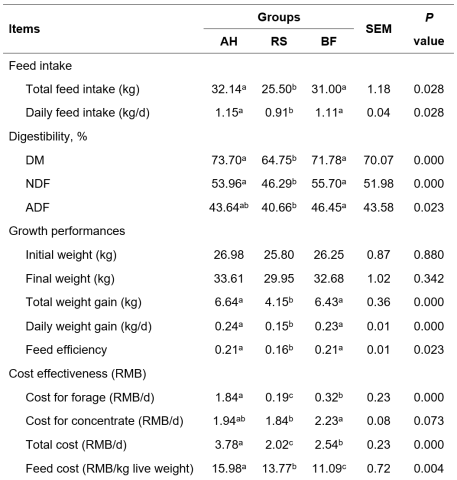

Kyawt et al. (2024) conducted an animal experiment to investigate the growth performance and the economic benefit for farmers. As shown in Table 3, the total feed intake and the average daily feed intake in the bio-fermented group were similar to the alfalfa group (positive control) and significantly higher than that of the untreated group (negative control). Compared with the untreated rice straw, the digestibility of DM, NDF, and ADF significantly increased, and were almost similar to the values for the alfalfa group. The weight gain and feed efficiency of the bio-fermented group were both significantly higher than that of untreated group and were similar to the alfalfa group. It seems that the bio-fermented rice straw can replace the alfalfa in feeding sheep if the same levels of energy and protein are used. The cost effectiveness showed that the feed cost (per kg live weight gain) was significantly reduced when bio-fermented rice straw was used. Feeding of bio-fermented rice straw does not have a negative impact on the growth performance and can reduce the feeding cost significantly.

Table 3: Effect of feeding rice straw silage (bio-fermented) on growth performance and feed cost of Hu sheep (Kyawt et al., 2024)

DM = dry matter intake, NDF = neutral detergent fibre, ADF = acid detergent fibre, AH = the group fed with alfalfa (positive control),

RS = the group fed with untreated rice straw (negative control), BF = the group fed with bio-fermented rice straw.

Profit for companies preparing the rice straw silage

Government of China encourages farmers to use crop residues as feed resources and companies to bioferment them. The motivation is alleviation of feed shortages and prevention of crop residue burning. The government pays ‘incentive in the form of cash (called stipend)’ to the farmers for using the crop residues and to the companies to produce biofermented crop residues. As an example, we present a case of a company in Jiangsu province to explain the economic benefit. The farmers, if their rice straw is harvested by the companies, get paid 450 RMB/ha, of which 375 RMB is contributed by the national government and 75 RMB by the local government, i.e. Jiangsu province. The company does not need to pay the farmers. It only arranges machines to harvest rice straw from the farmers’ fields. The company also gets a stipend from the government, which is 25 RMB/metric ton of the green straw treated. As approx. 15 metric tons of green rice straw are obtained per ha, the stipend from the government is 375 RMB/ha. The selling price of the biofermented rice straw is 500 RMB/metric ton, giving an income of 525 RMB/metric ton for preparing and selling the fermented rice straw. This cost includes the fee paid for harvesting, transportation, processing, and labor. The Lactobacillus culture used by this company is from Lactosan GmbH & Co., Kapfenberg, Austria. Several machines are necessary to harvest and process the rice straw on time. Harvesters are expensive. For buying harvesters and other machines used for the biofermentation, the companies also get financial assistance from the government, an example being loan at low interest.

The company under reference in Jiangsu province has contracts with farmers covering 26,667 ha for procurement of straw after the harvest. It is operational 365 days in a year as they make wheat straw silage in May-June, maize silage in August-September, and rice straw silage in October-November. The economic profit is substantial for the company. It is an excellent example of a public-private partnership.

Indian case study

Introduction

India, the second largest agro-based economy generates a large amount of agricultural waste, including crop residues. The increase in availability of crop residues over the years has largely been due to the increase in production of paddy, wheat and other field crops resulting in higher grain production and consequently higher availability of crop residues from these crops. Crop residues are field residues that remain in an agricultural field after the crop is harvested commonly include stalks and stubble (stems), leaves and seed pods. The crop residues serve as an important source of roughage, which meets the partial requirements of livestock. It has been reported that crop residues constitute a major source of fodder (54%) for livestock feeding in India (Hegde, 2006). Although these crop residues are considered valuable by the livestock keepers, there has been a lot of wastage in many parts of the country.

Major crop residues available in North India are paddy straw and wheat straw due to adoption of Rice-Wheat cropping systems in large area. This cropping system is prevalent in northern region mainly due to suitable agro-climatic conditions for cultivation, optimum MSP and largescale procurement of grains by public/private sector agencies. However, due to lack of demand in local markets, paddy straw is being burnt by the farmers in Punjab, Haryana and Uttar Pradesh states. Burning of paddy straw not only contributes to greenhouse gas (GHG) emissions but also widens the gap between demand and supply of livestock forages in the country.

In the past, various physical, chemical and biological methods have been tried for improving the utilization of straws as livestock feeding (Sarnklong et al., 2010). However, most of these methods are not practically and commercially applicable for the livestock farmers under field conditions owing to their various limitations. Despite efforts by different agencies, paddy straw is being burnt after combine-harvesting, mainly due to limited window for clearing the fields for sowing the wheat crop after harvesting of the paddy crop. Any attempts for immediate collection of freshly harvested biomass from the field and conserving them in the form of silage would provide a promising approach for control of residue burning and help improve the availability of fodder for livestock feeding. Further, this highly compacted/densified ensiled residue could be transported to nearby fodder deficit states.

Status of crop residues in North India

India produces about 500 million metric tons (MMT) of straws/stovers annually (ICFA, 2022). The generation of crop residues is highest in Uttar Pradesh (60 MMT), followed by Punjab (51 MMT) and Maharashtra (46 MMT). Among different crops, cereals generate maximum residues (352 MMT), followed by tubers (66 MMT), oilseeds (29 MMT), pulses (13 MMT) and sugarcane (12 MMT). In India, approximately 90 MMT of paddy straw are disposed of by burning. It is estimated that paddy is being cultivated in 3 million hectare area in Punjab and about 50 quintals of wet paddy biomass is generated per hectare (Agri and Food Technology Fair, 2022). Around 75-80% of the area under paddy is machine-harvested, and approximately 95% of paddy straw is burnt annually in the state (Singh et al., 2018). The farmers in Punjab State mainly use wheat straw as dry fodder so most of the paddy straw is surplus. A survey on the end-use of rice and wheat straws in the state of Punjab showed that less than 10 percent of rice straw and 40% of wheat straw produced annually is used as animal feed.

Burning of crop residues

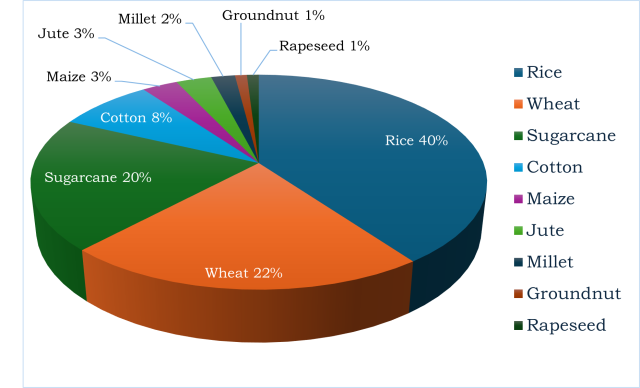

Burning of crop residues in India is a well-recognized problem, arising and increasing since the late 1980s (Sarkar et al., 2018). The rapid introduction of the combine-harvesters constitutes a game changer because of the less time spent in crop harvesting in comparison to manual harvesting. Manual collection of straw in the field is uneconomical due to the high labor cost. But use of combine harvesters leads to larger amounts of straw that are left spread out on the field. Most farmers burn these straws in the field, mainly due to higher labor cost, lack of availability of equipment for straw collection, sufficient availability of wheat straw for feeding, limited time-window between paddy harvesting and sowing of wheat crop, and the lack of awareness about use of paddy straw for livestock feeding. Rice, wheat and sugarcane crop residue burning together contribute more than 80% of the total biomass burning from different crops in India (Figure 7). Any intervention targeted at arresting the residue burning in these crops will significantly reduce this menace.

Figure 7. Contribution of different crops in residue burning - Source: Ministry of New & Renewal Energy, Gol)

At present, North India finds itself in the midst of a paradoxical situation of prodigious production of paddy and wheat (food grains) for meeting the country’s food security needs, co-existing with increasing problem of straw disposal. About 85-90% of this paddy straw is burnt in the fields, and to some extent, wheat straw is also being burnt during the rabi harvesting season. States like Uttar Pradesh, Punjab and Rajasthan are the epicentres of maximum crop residue burning in North India (Figure 8). The farmers resort to burning paddy straw as the window between harvesting of paddy and sowing of wheat is of just 2-3 weeks which does not allow for time consuming operations of clearing paddy straw from the fields. The major challenge currently to the states is to effectively handle the problem of crop residues.

Figure 8: Status of crop residue generation and burning (million metric tons) (Source: Ministry of New & Renewal Energy, Gol)

Use of paddy straw as a feed

Several benefits are also forgone when residues are burned – such as their use as animal feed, construction material, ethanol production, or soil quality and nutrient retention by tilling left-over residues back into the soil (Gupta, 2019). Considering the current fodder scenario in the country, use of paddy straw as such or after enrichment would be more beneficial for dairy farmers. A large-scale attempt for collection of green paddy stubble from the farmers’ field, immediately after the harvest, and ensiling them with enzymes and silage culture appears to be a promising alternative to residue burning in North India.

Feeding to ruminants

The feeding of paddy straw to ruminants is not commonly practiced by the farmers in North India. However, it has been documented that the paddy straw can be fed up to 60% in combinations with other ingredients such as concentrates, molasses, or legumes to improve palatability, protein content, intake and digestibility by the animals (Aquino et al., 2020). The average dry matter digestibility of paddy straw ranges from 45 to 50% in ruminants.

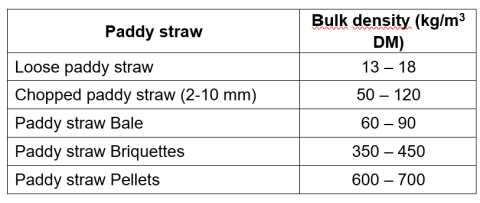

Devendra (1997) reported that the amount of paddy straw that ruminants can daily consume can be as high as 1.2 kg (DM)/100 kg of live weight. Paddy straw intake, however, varies among animals and is influenced by the proportion used in the ration. The intake of paddy straw also varies according to the manner in which it is prepared, processed, and fed to the animals. Physical processing (chopping) or the use of chemical or microbiological treatments considerably improves an animal’s paddy straw intake. When offered as is, paddy straw intake is lower because it is bulky or occupies more space in the rumen. Average bulk density of loose and processed paddy straw is given in Table 4.

Table 4: Bulk density of loose and processed paddy straw

Source: Aquino et al. (2020).

Processed straws as feeding

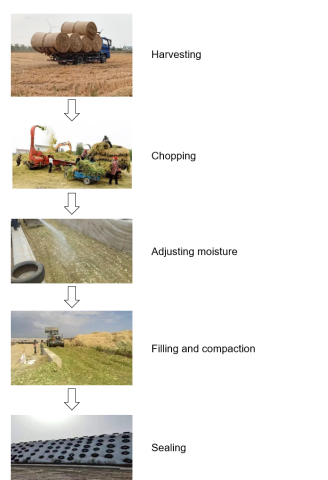

Paddy straw could be used for livestock feeding by densifying it with essential nutrients, making silage/pellets/blocks or Total Mixed Ration (TMR). These enriched straw silage/pellets/blocks and TMR could be transported from surplus region to nearby fodder deficit states. The nutritive value of the straws can be improved by using various treatments of straws such as physical (soaking & wetting, chopping, grinding and pelleting, steaming under pressure, gamma irradiation), chemical (alkali spray treatment, ammonization of straw, calcium hydroxide treatment, treatment with oxidative reagents, treatment with acids) and biological treatments (white-rot fungi treatment, treatment with enzymes). Many of these processes are technologically feasible and are also economically viable under field conditions. However, due to lack of extension activities, many of these technologies did not reach the farmers’ doorstep. One of the most promising approaches is to secure the green paddy stubble from the farmers’ field immediate after the harvest (Figure 9) and ensile it with ligno-cellulose degrading enzymes and/or Lactobacillus based silage culture.

Figure 9. Securing green paddy straw from farmers’ fields (Photo credit: M. R. Garg)

Paddy stubble silage

National Dairy Development Board (NDDB), Anand conducted small scale studies for making silage from green paddy stubbles. Green paddy stubbles were collected from the field immediately after harvesting, chopped and treated with silage culture Lactobacillus plantarum) (Kem LAC® HD Dry (016314) Kemin, USA) @ 1.0, 2.0 and 3.0 g per metric ton. The treated paddy stubble was tightly compacted manually and filled in high-density polyethylene (HDPE) silage bags (40 kg capacity) (Figure 10). After 30 days of incubation period, bags were opened, and silage samples were analyzed. It was found that a good quality silage (pH 4.4 with very good aroma) from green paddy stubble can be prepared using 3.0 g silage culture per metric ton. In another study, chopped paddy stubble was treated with silage culture @ 1.0, 2.0, 3.0 g per metric ton and multi-enzyme @ 0.5, 1.0 litre per metric ton in different combinations. Stubbles were round baled (50 kg weight) with the help of a baler-wrapper machine and ensiled for 60 days. Results indicated that 2.0 g silage culture and 1.0 litre multi-enzyme per metric ton were effective for making a good quality (pH 4.1) paddy stubble silage. The stubble silage was palatable by the cattle (Figure 11). Studies are required that evaluate the impact of feeding paddy stubble silage on milk production, reproduction and health in dairy animals in India.

Figure 10. Storage of paddy baled silage (Photo credit: M. R. Garg)

Figure 11. Feeding of paddy straw silage to dairy animals (Photo credit: M. R. Garg)

Large-scale initiative

Unpredicted sky-high prices of dry fodder are very common in different seasons as well as in different parts of the country. During recent past, the market price of dry fodder shot up significantly and resulted in hardship for rural milk producers, and adversely affected profitability and livelihood of dairy farms. In such situations, paddy stubble silage could be an alternative source of livestock feeding. Large-scale initiative for collection of paddy stubbles from the farmers’ field immediately after the harvest, ensiling them with silage cultures and enzymes at organized places could be a promising intervention for avoiding crop residue burning. The surplus paddy stubble silage could also be transported to adjoining fodder deficit states, which would help address the fodder shortage in the country.

Fodder-Plus Farmer Producer Organizations (FPOs) working in the northern region could be instrumental in establishing forward and downstream linkages for production and distribution of paddy stubbles silage. This would encourage the farmers to prevent burning crop residues and help enhance feed ingredient availability. Further, decision makers, young entrepreneurs, progressive dairy farmers and NGOs could join hands in addressing the triple-burning issues: crop residue burning, fodder shortage and climate change for the betterment of future life.

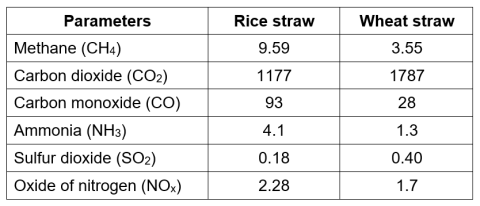

Avoiding GHG emissions by diverting straws from burning to feeding

Burning of crop residues contribute to greenhouse gas (GHG) emissions – causing global warming (Fagodiya et al., 2017). It also contributes air pollutants – namely, carbon monoxide, oxides of sulphur and nitrogen, ammonia, non-methane volatile organic compounds, polycyclic aromatic hydrocarbons, elemental carbon, organic carbon and particulate matter and smoke – causing air pollution and thereby threats to human health (Jain et al., 2014). Out of the total gases emitted from crop residue burning in India, almost 66% is carbon monoxide (ICFA, 2022).

Crop residue burning is also a major source of black carbon (BC) in the environment. Crop residue burning, particularly in Punjab and Haryana states is an important source of BC that forms the South Asian brown cloud (Bikkina et al., 2019). During the dry and high-loading winter period, when the residue burning takes place, westerly winds push BC along the Indo-Gangetic Plains, which also impacts adversely the national capital, Delhi (Bikkina et al., 2019). It has been estimated that BC emission from residue burning ranges between 27 to 83 Gg annually for the whole of India, and 1.5 to 47.2 Gg for Punjab (Andrea et al., 2022). Based on the average emission coefficient for burning paddy straw and wheat straw (Table 5), millions of metric tons of GHG emissions could be prevented just by diverting the straw from burning to animal feeding.

Table 5: Emission coefficient (g/kg) for residue burning

Source: Chethan et al. (2020).

Conclusion

Immediate collection of freshly harvested crop residues from the farmers’ field and ensiling them with enzymes and silage culture could be a game-changer. Bio-fermentation of crop residues can have ‘triple-wins’: benefit for the farmers, the companies and the environment. There are many other countries that lack feed resources. Bio-fermentation of crop residues is a good technology for such countries. But the entrepreneurs will have to budget the input costs, especially the cost for the machines. The use of machines for the biofermentation increases amount, decreases cost, and increases quality of the treated straw. The quality of the treated rice straw, its acceptability by animals and shelf-life are better than the untreated straw; and it forms a good feed for ruminant livestock including dairy animals. Although, in this paper the technology is illustrated using rice straw, it can be used for any crop residues such as wheat, sorghum or barley straws.

It is hoped that this article help create awareness among entrepreneurs, decision makers, Fodder plus Farmer Producer Organizations (FPOs), academicians, progressive dairy farmers, NGOs and science managers about the current status and potential use of crop residues as a feed for milk and meat producing animals.

References

- Agri and Food Technology Fair (2022). The 15th edition of Agri and Food Technology Fair was organised by Confederation of Indian Industry (CII) during 4th to 7th November, 2022 at Chandigarh.

- Andrea S. Downing, Manish Kumar, August Andersson, Amar Causevic, ¨Orjan Gustafsson, Niraj U. Joshi, Chandra Kiran B. Krishnamurthy, Bert Scholtens, Beatrice Crona (2022). Unlocking the unsustainable rice-wheat system of Indian Punjab: Assessing alternatives to crop-residue burning from a systems perspective. Ecological Economics, 195: 107364.

- Aquino Daniel, Arnel Del Barrio, Nguyen Xuan Trach, Nguyen Thanh Hai, Duong Nguyen Khang, Nguyen Tat Toan, and Nguyen Van Hung (2020). M. Gummert et al., (eds.), Sustainable rice straw management. Springer Book ISBN 978-3-030-32373-8 (eBook), https://doi.org/10.1007/978-3-030-32373-8.

- Bikkina, S., Andersson, A., Kirillova, E.N., Holmstrand, H., Tiwari, S., Srivastava, A.K., Bisht, D.S., Gustafsson, ¨O. (2019). Air quality in megacity Delhi affected by countryside biomass burning. Nat. Sustain. 2, 200–205. https://doi.org/10.1038/s 41893-019-0219-0.

- Cann I, Cheng Y, Alhawsawi MAB, Moran Mallory, Li Y, Gong T, Zhu Y, Mackie RI. Rumen-targeted mining of enzymes for bioenergy production. Annual Review of Animal Biosciences, 2025, 13: 343-369.

- Cheng Y, Wang Y, Li Y, Zhang Y, Liu T, Wang Y, Sharpton TJ, Zhu W. Progressive colonization of bacteria and degradation of rice straw in the rumen by Illumina sequencing. Frontiers in Microbiology, 2017, 8: 2165.

- Devendra C (1997) Crop residues for feeding animals in Asia: technology development and adoption in crop/livestock systems. In: Renard C (ed) Crop residuals in sustainable mixed crop/livestock farming system. CAB International, Wallingford, pp 241–267.

- Fagodiya RK, Pathak H, Kumar A, et al. (2017). Global temperature change potential of nitrogen use in agriculture: A 50-year assessment. Sci Rep., 7: 44928. doi:10.1038/srep44928.

- Gupta, N. (2019). Paddy residue burning in Punjab understanding farmers’ perspectives and rural air pollution. March. https://www.ceew.in/sites/default/files/CEE W-Paddy-Residue-Burning-in-Punjab-Farmers-Perspectives-Issue-Brief-29Mar19.pdf.

- He X, Wu Y, Cai M, Mu C, Luo W, Cheng Y, Zhu W. The effect of increased atmospheric temperature and CO2 concentration during crop growth on the chemical composition and in vitro rumen fermentation characteristics of wheat straw. Journal of Animal Science and Biotechnology, 2015, 6: 46.

- Hegde. N.G. (2006). Livestock Development for Sustainable Livelihood of Small Farmers. In Souvenir of the 39th Annual General Meeting and 48th National Symposium on Energizing Rural India – A Challenge to Livestock Industry. Compound Livestock Feed Manufactures Association of India (CLFMA). Manesar. Haryana. August 26: 50-63.

- Hu G, Guo M, Cheng Y, Zhu W, Ondiek JO, Wahome RG, Adugna T, Padmakumar V. Analysis of factors affecting the nutritional composition of roughage using existing data: A case study on China and Africa. Field Crops Research, 2025, 324: 109796.

- ICFA (2022). Indian Council of Food and Agriculture. Report on “Crop Residue Burning – Challenges & Solutions”. New Delhi. Available at www.icfa.org.in

- Jain N, Bhatia A, Pathak H. (2014). Emission of air pollutants from crop residue burning in India. Aerosol Air Qual Res., 14(1): 422–430.

- Kyawt YY, Aung M, Xu Y, Sun Z, Zhou Y, Zhu W, Padmakumar V, Tan Z, Cheng Y. Dynamic changes of rumen microbiota and serum metabolome revealed increases in meat quality and growth performances of sheep fed bio-fermented rice straw. Journal of Animal Science and Biotechnology, 2024, 15: 34.

- Sarkar, S., Singh, R.P., Chauhan, A. (2018). Crop residue burning in northern India: increasing threat to greater India. J. Geophys. Res. Atmos. 123, 6920–6934. https:// doi.org/10.1029/2018JD028428.

- Singh R, Mahajan G, Kaur S and Chauhan BS (2018). Issues and strategies for rice residue management to unravel winter smog in North India. Current Science 114(12): 2419.

- Xu Y, Aung M, Sun Z, Zhou Y, Xue T, Cheng X, Cheng Y, Hao L, Zhu W, Degen A. Ensiling of rice straw enhances the nutritive quality, improves average daily gain, reduces in vitro methane production and increases ruminal bacterial diversity in growing Hu lambs. Animal Feed Science and Technology, 2023, 295: 115513.